Gear pumps / pump units: durable, variable and economical

RICKMEIER gear pumps and pump units perform a broad variety of tasks in a wide range of industrial applications: from lubrication circuits to pressure generation in hydraulic working systems or the transportation of liquids for oils and other flow media. In many applications, they work in the background, quietly creating the preconditions for reliable and problem-free operation of other machines. The gear pumps and pump units can be used in hazardous areas according to ATEX directive 2014/34/EU.

The R6 series of pumps/ R5 PLUS series

The launch of the new R6 pump series clearly demonstrates the capabilities of our team. In addition to evolutionary technical innovations and a new, clearly defined and aesthetically high-quality product language, the series of pump convinces users with real customer benefits and responsible sustainability. In the field of industrial product design, the R6 series of pumps received the iF Design Award 2021. The relaunch of our R5 series and the mechanically driven UNI pumps focuses on replacing leaded plain bearings with lead-free ones.

Special products are customised in consultation with our customers worldwide. It goes without saying that all lead-free plain bearings have been extensively qualified by us as functional and service life-relevant components.

. Datasheet gear pump R36, R46

Standard version:

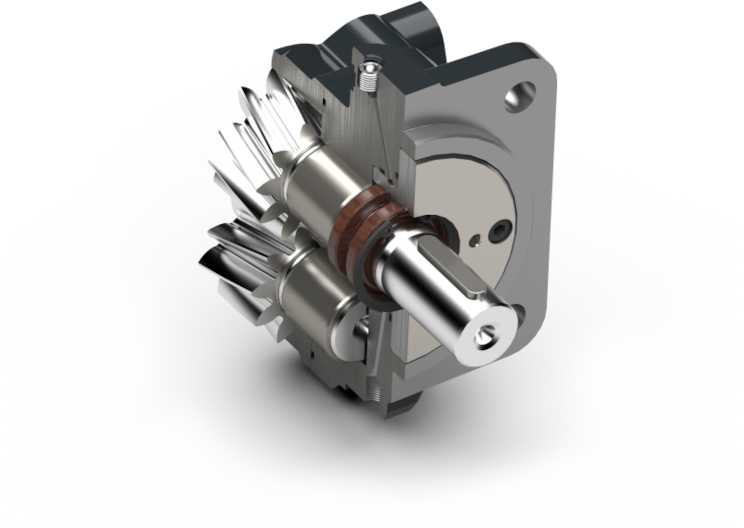

Gear pump R46 – New designed rear view

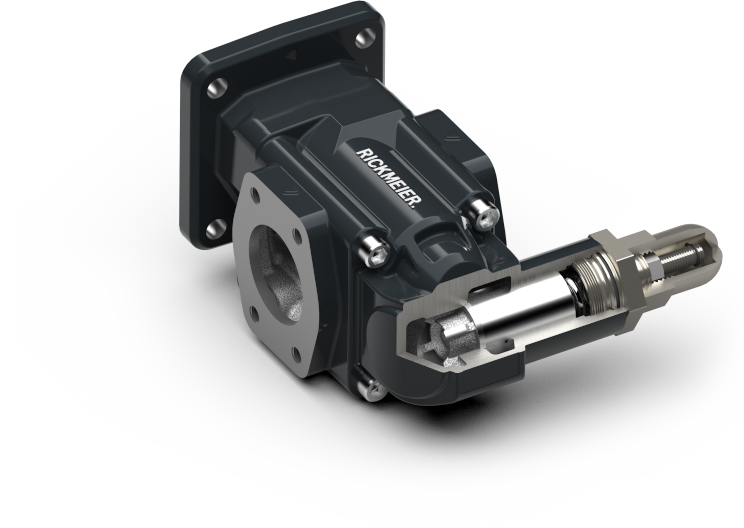

Gear pump R46 – View of the drive shaft

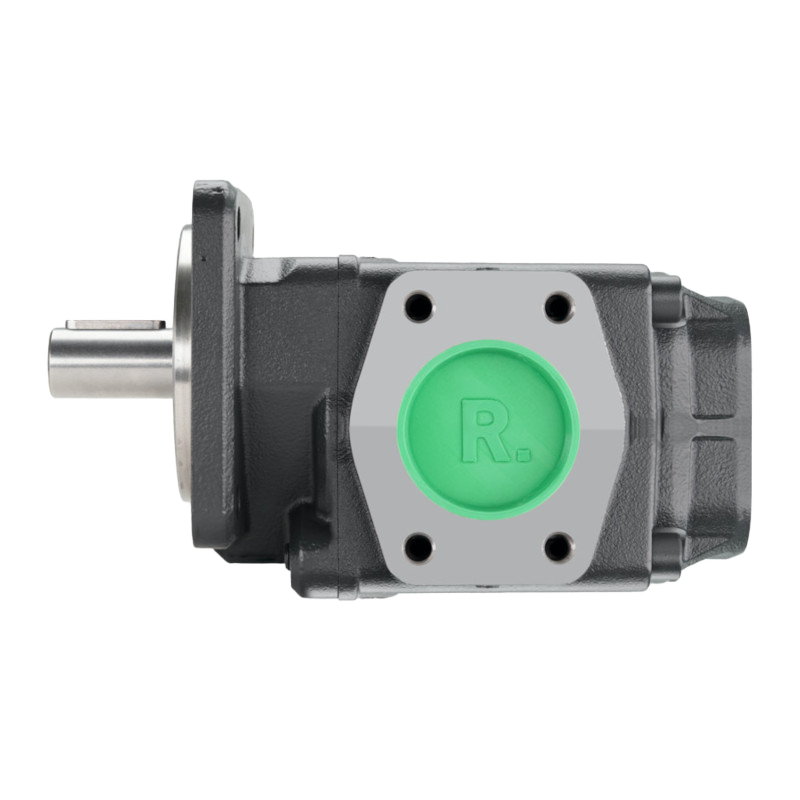

Gear pump R46 – Side view overlooking the characteristic sealing plug

Evolutionary technical innovations

With the relaunch of the tried-and-tested R5 Series, RICKMEIER is taking a decisive step into the future. In addition to winning the iF Award 2021 in the field of industrial product design, the new R6 Series convinces with evolutionary technical innovations based on more than 100 years of experience in the development and manufacture of gear pumps. The focus during implementation was on collaboration with international users with the aim of developing a pump series that delights customers and sets new benchmarks when it comes to efficiency, noise level, sensitivity to cavitation, weight and compatibility with a wide range of flow media.

Facts

- Expansion of the displacement volume

of up to 40% within existing sizes - Improved noise characteristics

and increased efficiency through optimized casing and gearing design - Reduction of sensitivity to cavitation

through improved flow design - Optimized compatibility

with a wider range of flow media and applications through high-quality seals and a variable, modular seal systemn - Low weight

through downsizing and compact design, up to 30% weight reduction

RICKMEIER ECODESIGN for responsible Sustainability

The term ECODESIGN stands for outstanding, environmentally friendly and future-oriented development of products. This goal significantly influenced the evolutionary development of the RICKMEIER R6 Series, leading to marked improvements.

Facts

- Improved noise characteristics

and increased efficiency through optimized casing and gearing design - Replacement of critical materials such as lead

- Reduction of the variant diversity by 70%

- Weight and material savings of up to 30%

- Optimized compatibility

with a wider range of flow media and applications through high-quality seals and a variable, modular seal system

The RICKMEIER-all-in-Pump Concept

This is clear evidence showing how user-oriented the development of the new R6 Series at RICKMEIER was. Features that were previously optional, such as high-quality FKM seals, are now integrated as standard. The reduction in the number of executions makes it easier for users to select the right pump type for their application.

Facts

- Noise optimization integrated as standard

- Lead-free bushes and FKM seals already included in the standard model

- Number of executions reduced by up to 70%

- Simplified selection of the correct pump type

The optimized RICKMEIER Modular System

The RICKMEIER engineers and technicians have developed a pump series that offers users worldwide a wide range of new possibilities. This shows that, right from the development phase, the process was customer- and solution-oriented.

Facts

- 100% interchangeable with the well-known R5 Series

- Standard version already covers many areas of application

- Easier adjustment of the pumps to special requirements

(modular seal system) - Expansion of the displacement volume

within existing sizes (better power to weight ratio) - Adapted SAE connection ports,

pressure side can be optionally reduced by one size in each case

The new RICKMEIER Product design

Winner of the iF Design Award 2021

With the development of the new R6 Series, RICKMEIER has not only realized evolutionary technical innovations, but also an impressive design concept. In a clearly defined design language, the R6 Series shows itself in a contemporary context and with high-quality product aesthetics. An appropriate design/weight ratio and responsible use of resources make the concept unique and earned it the iF Design Award 2021 in the field of industrial product design.

Facts

- Clearly defined design language

- High-quality aesthetics

- Uniform and clear product graphics

- Design can be transferred to other products

- Good ratio between weight and design

- ECODESIGN

(conservation of resources and sustainability)

Evaluated have been

Data and facts

Information

- Start of the R6 Series with the R46

- Volumetric displacement from 112 to 230 cm³ / revolution, i.e. Flow rate up to 690 L/min

- Other sizes and optional executions (modular seal system and pressure relief valve) will follow soon

Application limits

- Max. permitted operating pressure 25 ba

- Max. rotational speed 3000 rpm

Materials and execution

- Housing material: EN-GJL-250

- Seal material: FKM

- With lead-free composite plain bearings

Pump sizes

- R46/112

- R46/125

- R46/160

- R46/180

- R46/200

- R46/230