RICKMEIER oil supply systems: solutions for the mechanical engineering industry

RICKMEIER oil supply systems are developed and manufactured at our Balve location, to individual customer requirements and in accordance with the highest standards of reliability and durability.

Oil supply systems

Extremely high quality and a fair price-performance ratio have established RICKMEIER oil supply systems worldwide and stand for “Made in Germany”.

We offer personal project support from experienced engineers, from concept development to engineering and right through to the construction of the oil supply system. The flexible use of our own in-house gear pumps and pressure control valves allows us to find solutions tailored to specific customer requirements, depending on the application, as container, base plate or carrier plate systems. Verification that each system complies with the highest quality standards is carried out on our own test rigs by correspondingly qualified and certified employees and is a matter of course for RICKMEIER.

RICKMEIER oil supply systems are used in transmission and drive technology, compressor and turbine construction, designed for wind generation plants and for friction bearings in large diesel and electric motors, mills, roller plants, to name a few examples.

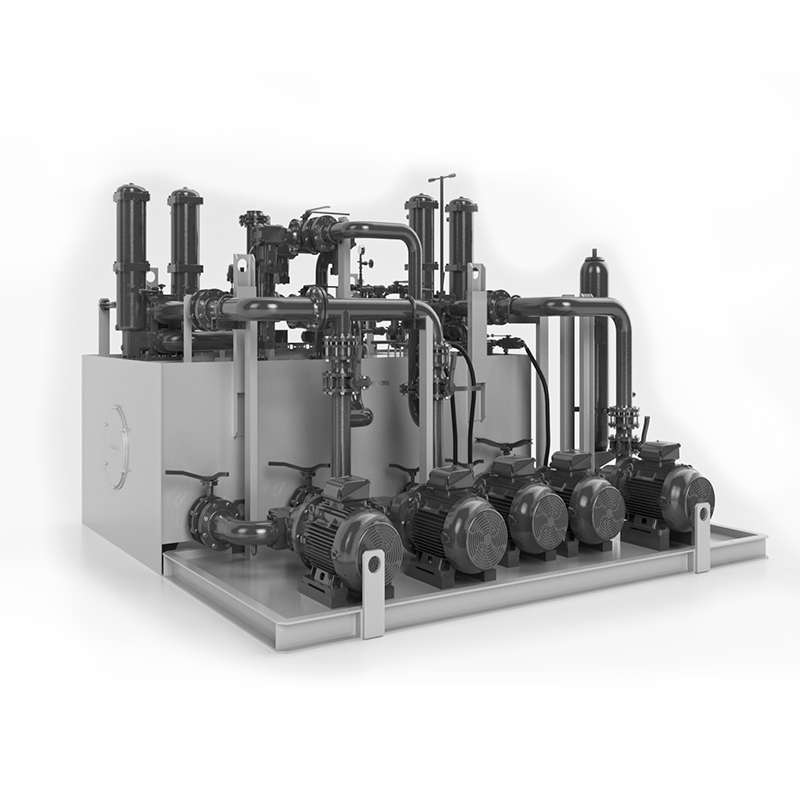

Oil supply system with container and base plate for supply of transmissions and slide shoe bearings (example: WS 3500 S-2x R65/400)

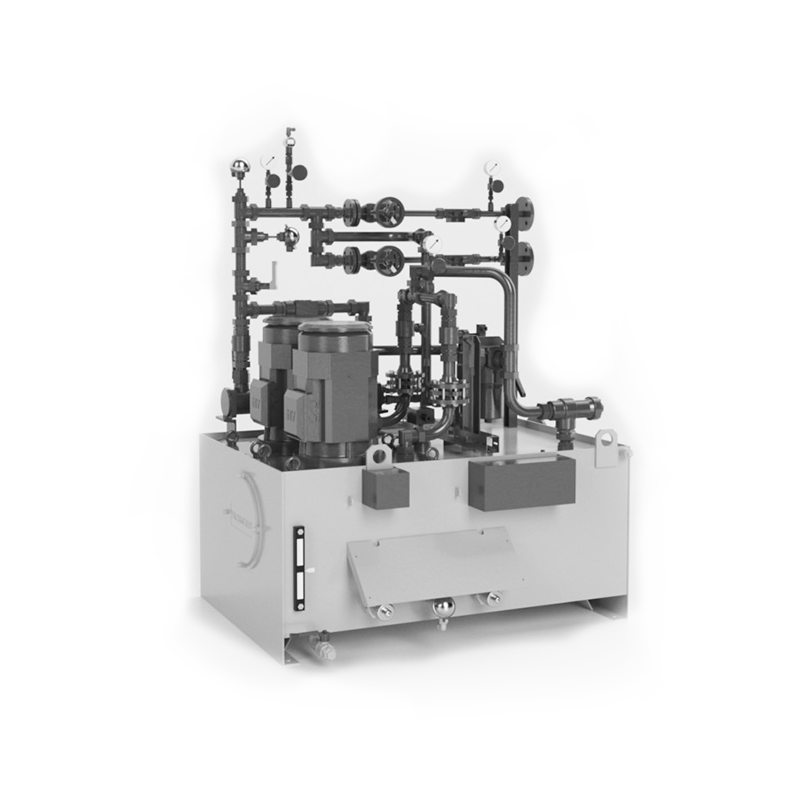

Container system for oil supply system to main gearbox of a paper machine (example: WS 400 S-2xR45/80)

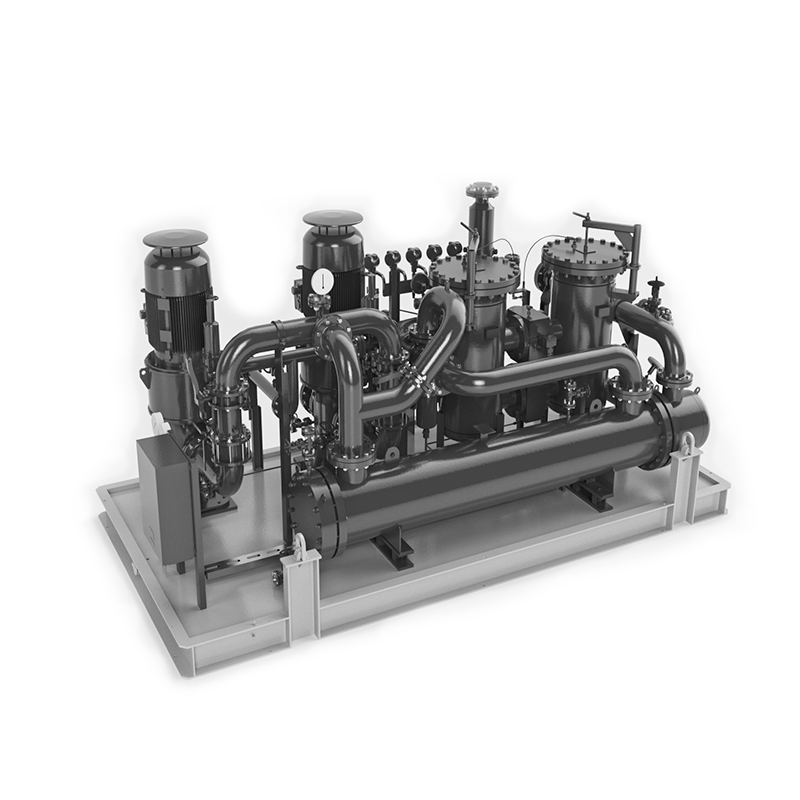

Base plate system for oil supply to main gearbox of an extruder line (example: GP-2xL2NG-116/180)

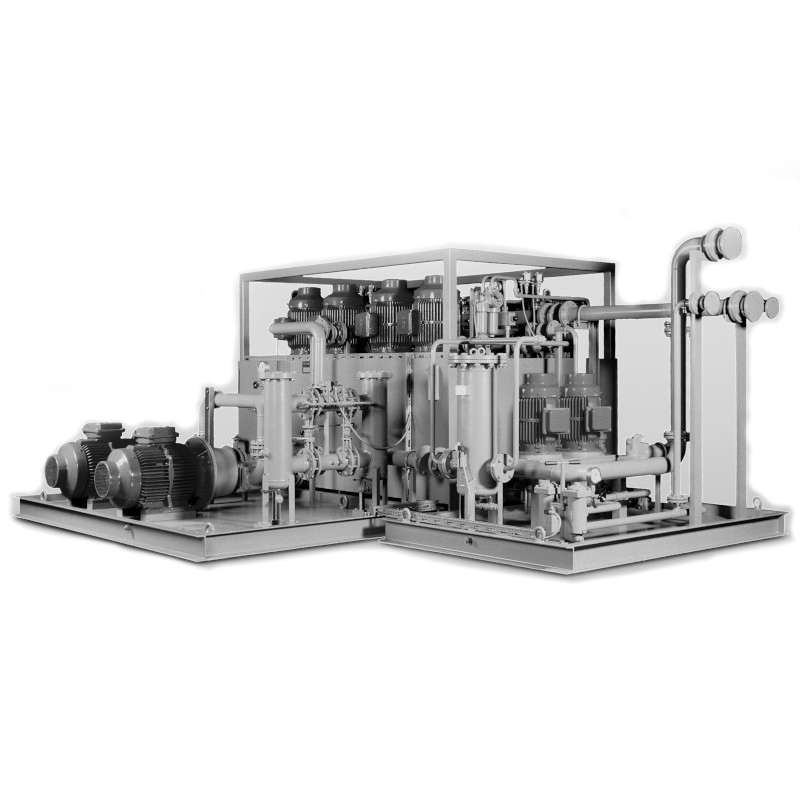

Base plate system for oil supply to marine drives (example: GP-L2NG 164/190)

Oil supply system with container and base plate for supply of transmissions and slide shoe bearings (example: WS 6000 S-2xR95/710)

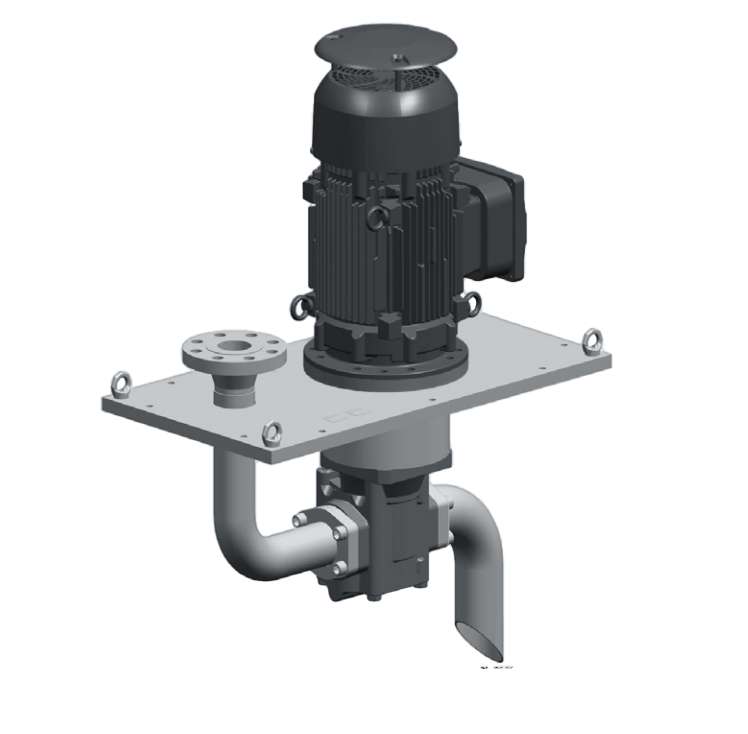

Mounting plate units

RICKMEIER supplies fully configured mounting plate units for installation in existing oil tanks and machines.

RICKMEIER mounting plate units are available as standard with gear pumps of sizes R25 to R65 and can be individually adapted to customer requirements. The units are equipped with three-phase asynchronous motors as standard, but also available with single-Phase AC motors and DC motors of various voltage levels on request.

Examples:

Mounting plate unit (example R65)