Gear pumps / pump units: durable, variable and economical

RICKMEIER gear pumps and pump units perform a broad variety of tasks in a wide range of industrial applications: from lubrication circuits to pressure generation in hydraulic working systems or the transportation of liquids for oils and other flow media. In many applications, they work in the background, quietly creating the preconditions for reliable and problem-free operation of other machines. The gear pumps and pump units can be used in hazardous areas according to ATEX directive 2014/34/EU.

RICKMEIER UNI pumps

Generally, reversing the direction of rotation at the pump input shaft reverses the direction of flow. RICKMEIER universal pumps always pump in one direction of flow, irrespective of the drive direction of rotation. This characteristic makes these mechanical driven pumps ideal for all applications where a reversal flow direction is undesirable.

Thanks to the special design of this internal gear pump series, switching valves are not required. This means that RICKMEIER UNI pumps can be simply integrated into wind power plants, marine transmissions or gas generators, for example. If the direction of rotation is reversed, the bi-rotational pump switches over automatically, at the same time maintaining the direction of flow. The sophisticated design with a minimum number of parts offers significant advantages over other solutions, such as lower pressure losses even at low temperatures and high oil viscosities.

RICKMEIER UNI pumps are extremely low-maintenance and require no wear parts such as seals and valves. As a result, they can be operated without maintenance effort over extremely long operating times. They cover displacement volumes of 35 to 160 cm³ per revolution, which corresponds to a flow rate of up to 400 litres per minute. The mechanical driven RICKMEIER pumps can be supplied with a wide range of casings and customised drive concepts. Our RICKMEIER engineers and technicians will be pleased to help you with further information and solutions.

Standard version:

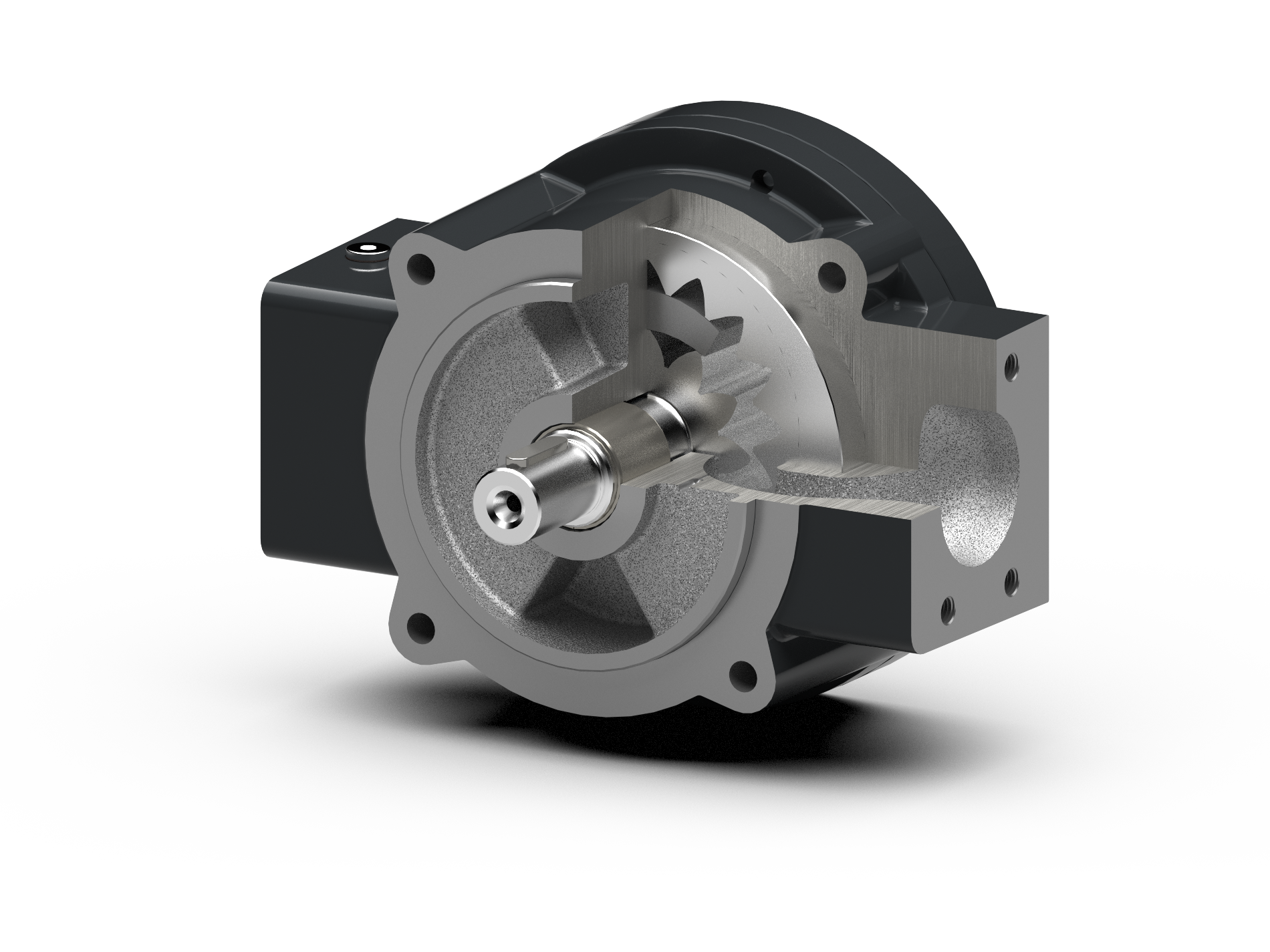

UNI pump with SAE connections in cross-section (example: R6.0/160)

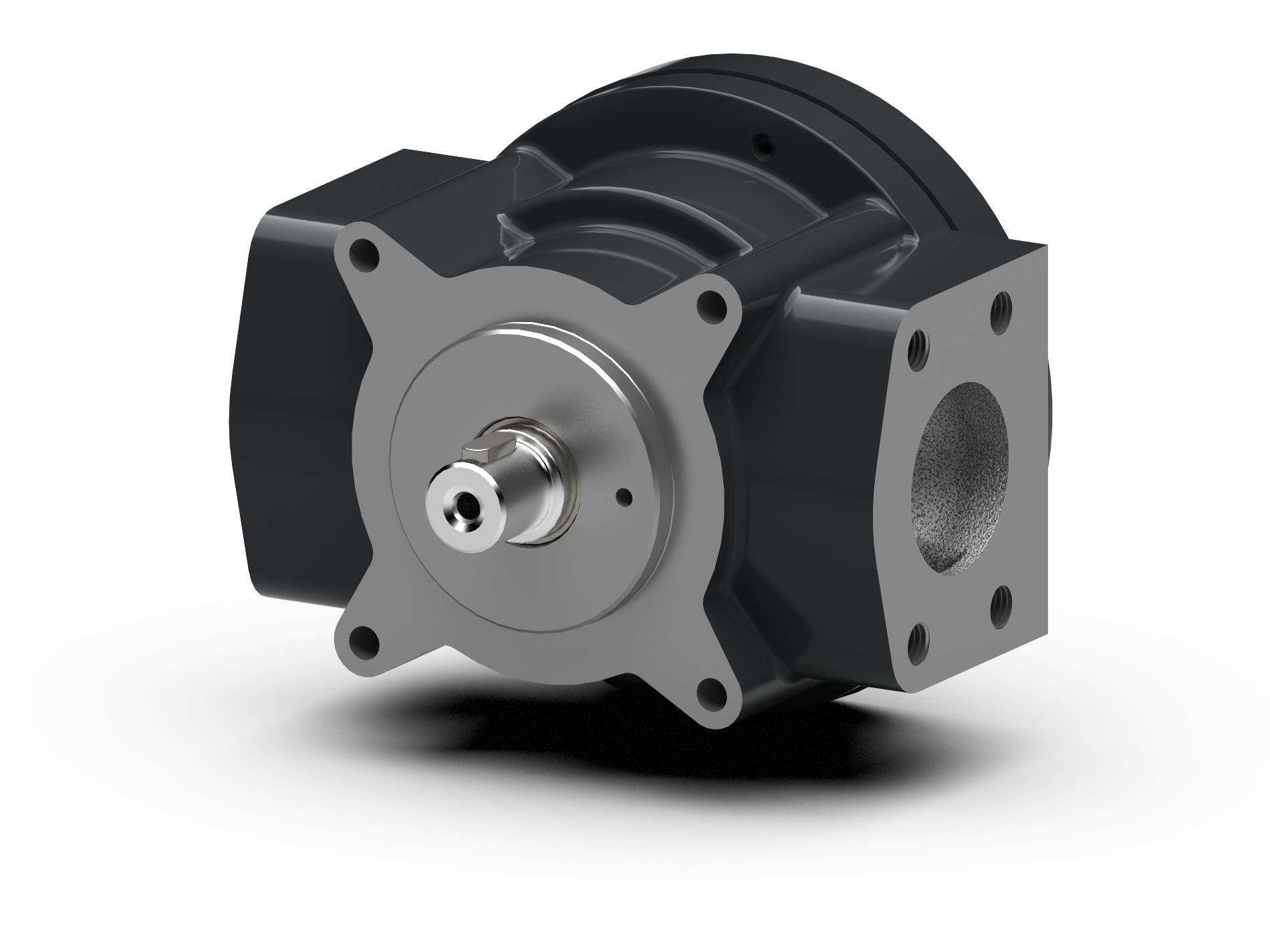

UNI pump with SAE connections (example: R4,5/54)

Special versions (examples):

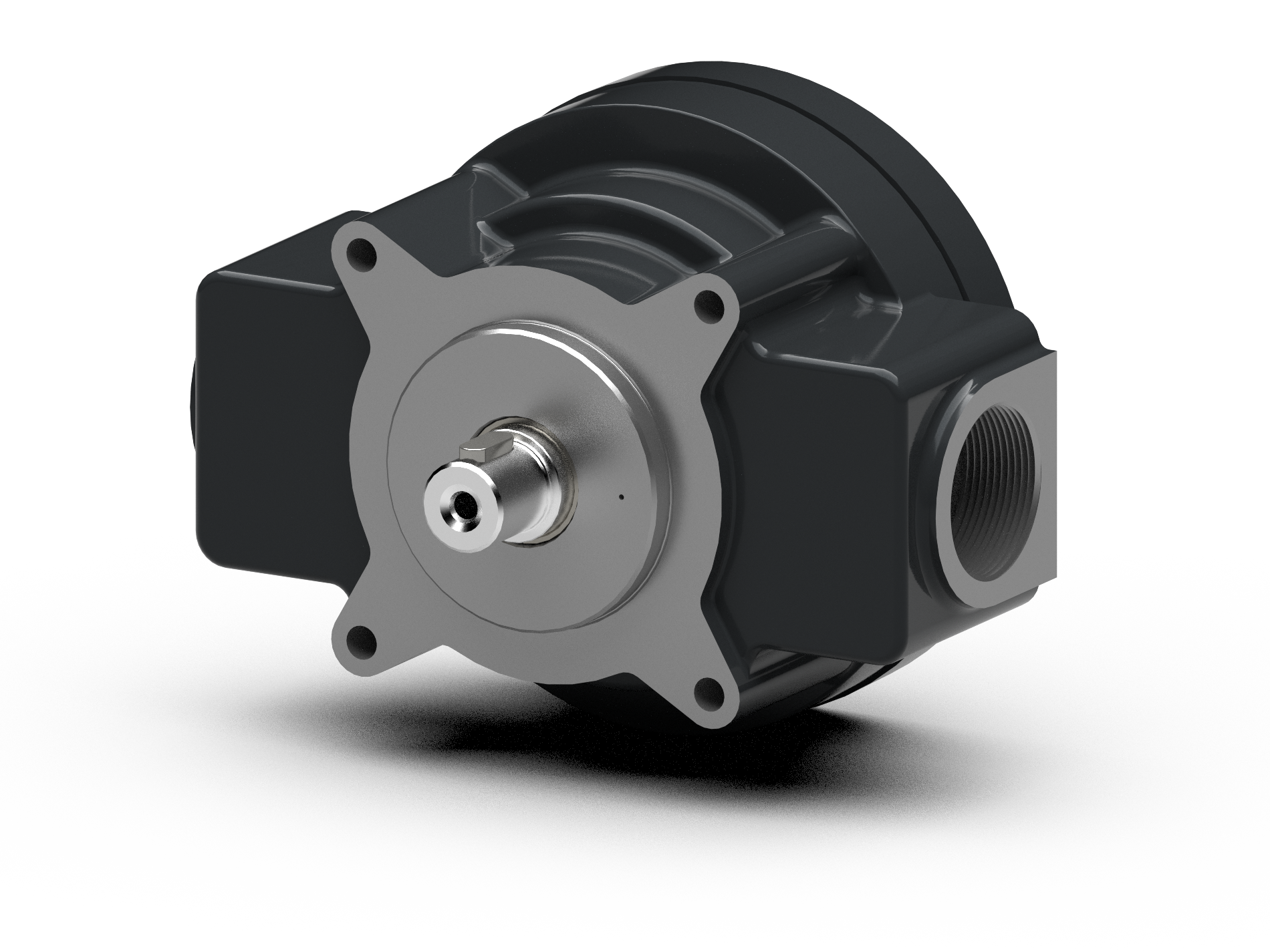

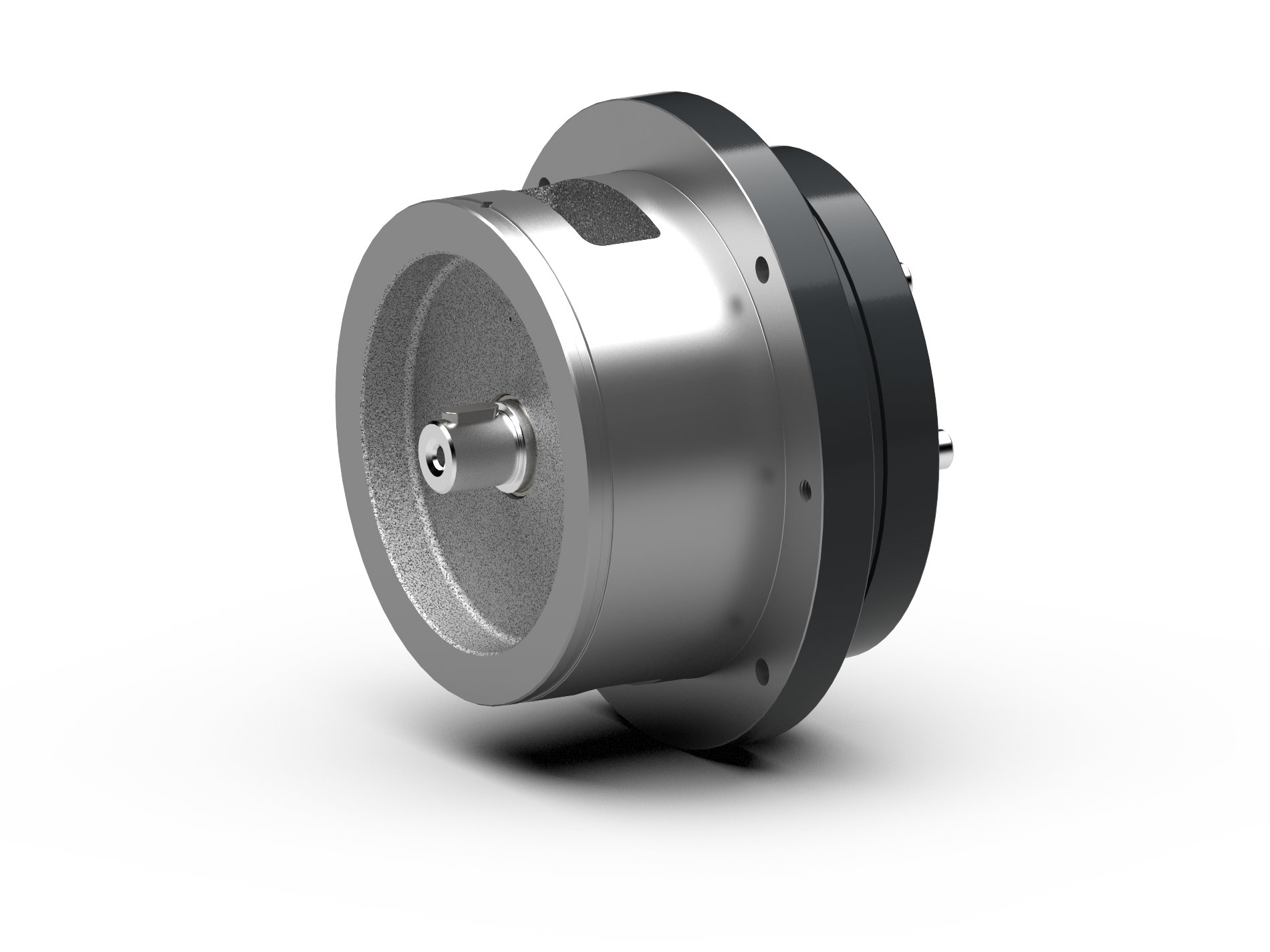

UNI pump with pipe thread connections (example: R4.5/45)

UNI pump with integrated pipework (example: R4.0/35)

UNI pump with integrated pipework and clutch (example: R4.5/45)

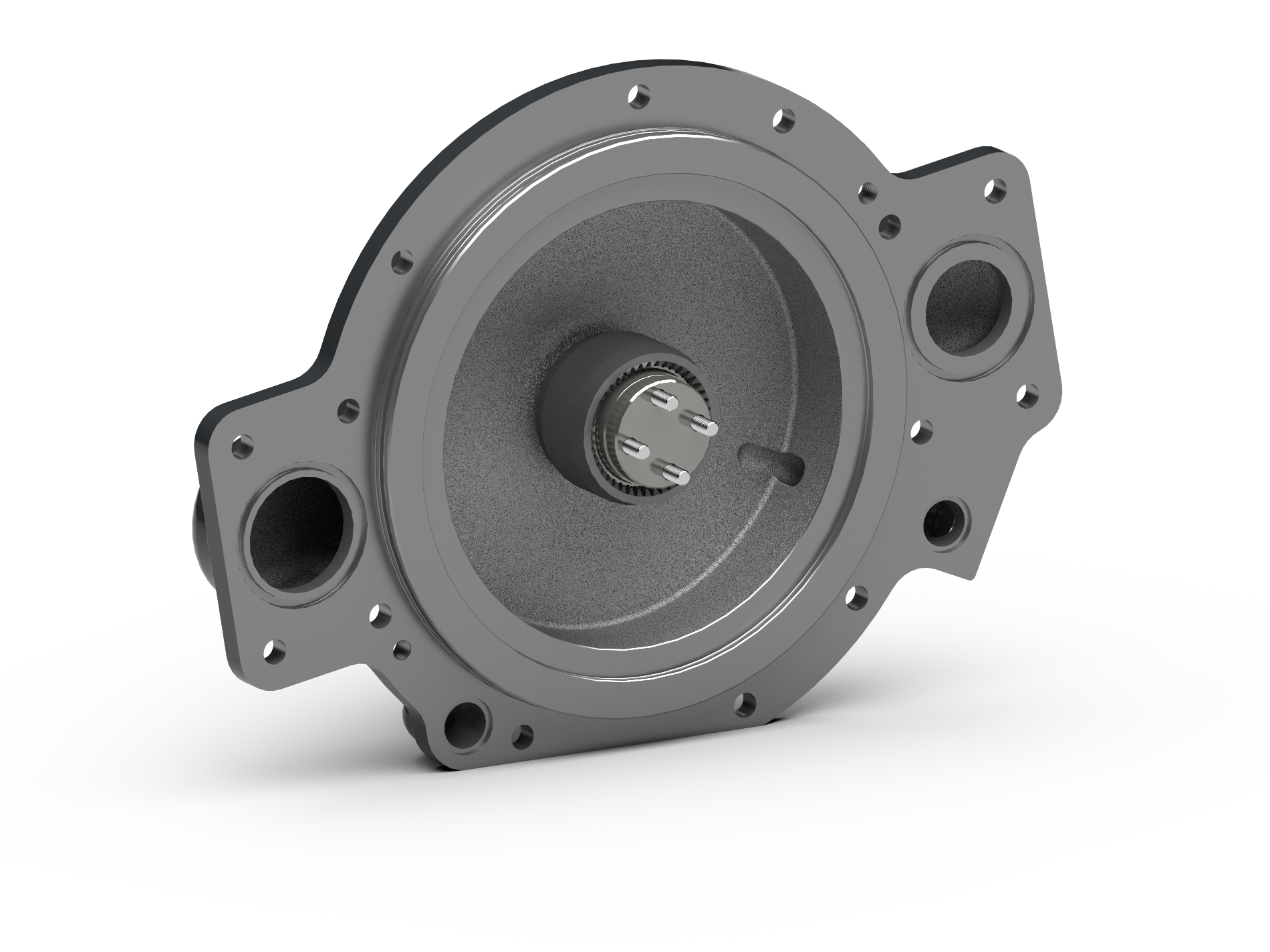

UNI pump as a plug-in pump (example: R4.5/45)

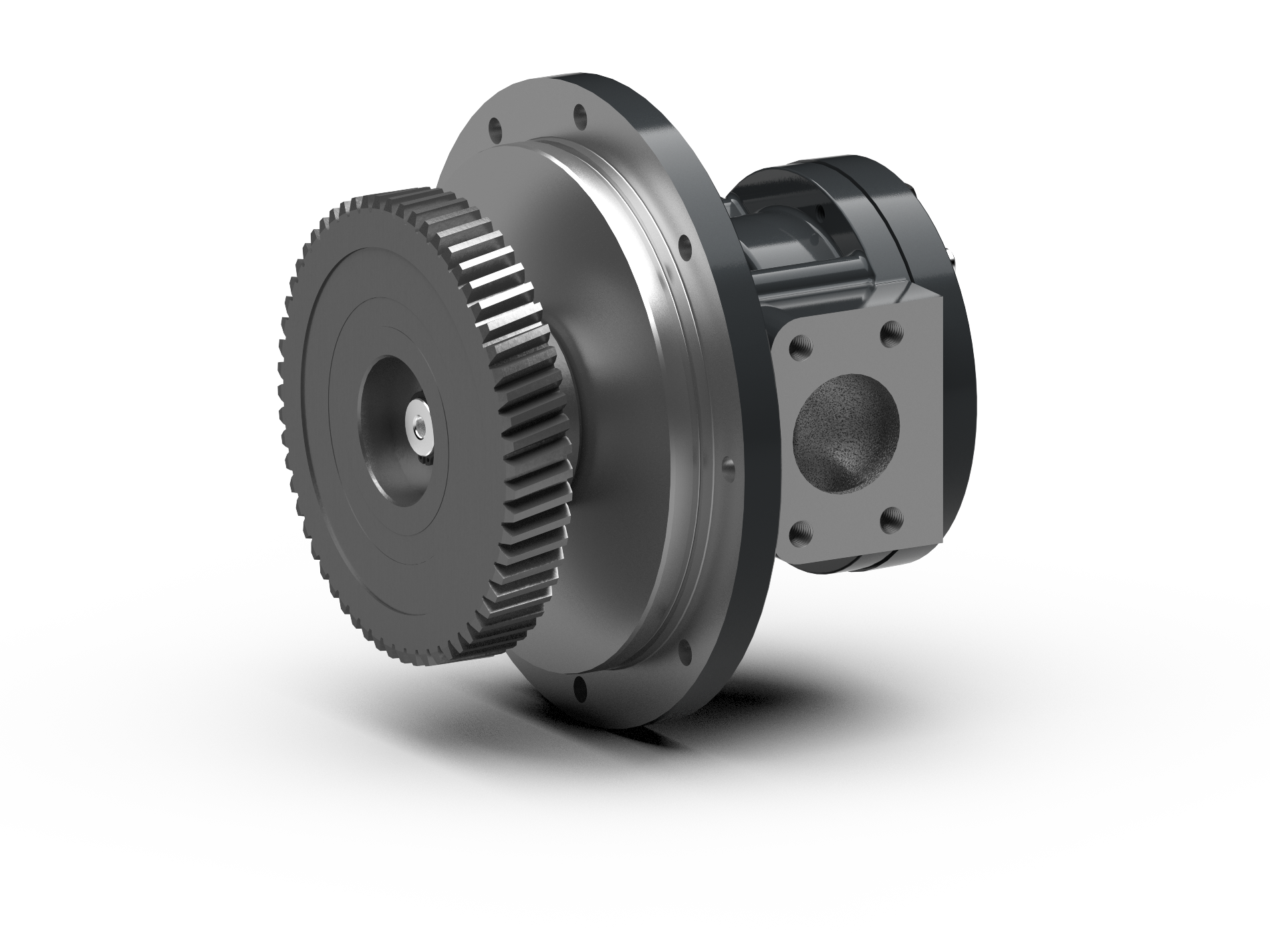

UNI pump with attachment bearing and pinion (example: R4.5/54)